Flax Field Lab

Summary of Flax growing trials in the Market Garden at Lauriston Farm in 2023 and plans for trials in 2024

In 2023 we participated in the Innovative Farmers Flax Field Lab facilitated by the Scottish Soil Association in collaboration with the James Hutton Institute and Edinburgh College of Art at the University of Edinburgh.

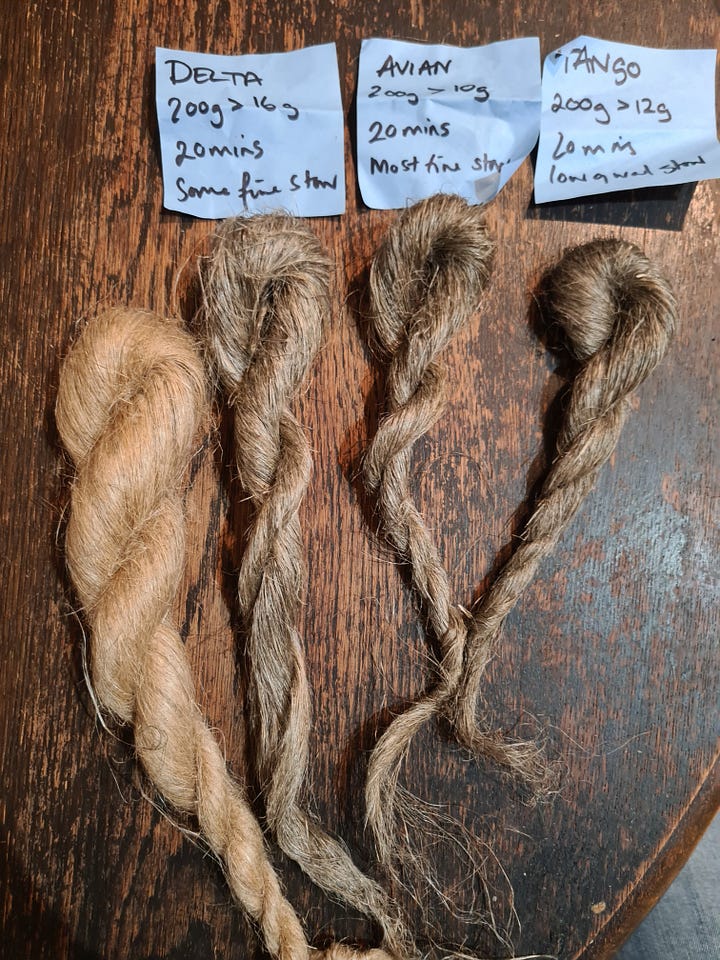

The main aim of the field lab was to compare the performance of 3 new Dutch-bred varieties of flax (Avian, Delta and Tango) in Scottish growing conditions. Two secondary objectives were to gain and share experience of the hand-harvesting and retting process, and to compare the fibre quality of the three varieties.

For the farm we were also interested in exploring this crop as part of rotations within our Market Garden and Agroforestry systems. Having grown small amounts of flax previously we found people were really intrigued to connect with fibre producing plants and could connect with the land in a different way through this material interaction. We were also really excited at the possibilities to collaborate with fibre and textile artists who were looking at re-invigorating a lost industry, creating opportunities for new land based livelihoods and offering new regenerative and local alternatives to an exploitative and extractive fashion industry.

As we start to begin our 2024 trials, the purpose of this note is to act as a reference to how we grew and harvested the crop in 2023 at Lauriston Farm and resulting yields/lessons learnt.

There’s plenty written elsewhere that might be more appealing for folks interested in using the fibre or exploring linen!

Recommended links:

Innovative Farmers Flax Field Lab - information about the Field Lab

Fibreshed Scotland - a growing community of producers, makers, consumers, and educators who work with and promote locally produced wool, linen, leather and natural dye products.

Fantasy Fibre Mill - Scottish based flax growers, processors and designers

Berta’s Flax - a guild for the preservation and promotion of Flax craft

Best information I've actually found about growing Flax in Scotland so far is the snappily titled Flax: Its Culture and Preparation in Scotland, Ireland, and Flanders. Particularly with Reference to the Western Highlands and Islands of Scotland from 1851!

Sowing

Seeds were sown on 27/04/23 in a newly plowed/rotovated block from long term pasture. Beds were shaped into 1.2M wide with rakes however no amendments or compost were added prior to sowing.

I used Jang LJ-24, (14F-9R). It's a largish hole and the most suitable one we had but imagine there are others that may be better. This wheel and gear combo gave about 2-4 seeds every 2.7cm on row

Our beds are 1.2M wide, so allocated 25M per variety (30m2). We filled hopper with total seed for variety and went up/down beds until seeds were done. This ended up being nearly exactly 9 rows per bed (some very little extra at end which I just rolled onto bed until hopper was empty). Each row ended up being a bit over 10cm apart

Amount of seed per plot was as per sowing densities recommended by Elsoms

The beds weren’t meshed or irrigated and we didn’t put up any bird scare tape etc.

Table 1: Sowing rates. TSW = Thousand Seed Weight (g)

Growing, Harvest & Retting

There was a slow start to growth as seeds were sown just before a drought. Crop started to germinate 08/05/23 (11 days). First flowers noticed 27/06/23 (61 days). Traditionally Flax would be harvested around the 100 day mark, our first harvest was made 22/08/23 (117 days) - only about ½ was pulled at this point and laid out on neighbouring blocks for retting. The rest still looked quite immature and a second harvest of Avian and Delta was made on 31/08/23 (126 days) with a final harvest on 04/09/23 (130 days).

Another issue with harvest was time and energy - it is pulled by hand in bundles before being laid out on beds to rett. It’s definitely a task that is more fun with many hands making light work - also the weedier beds took far longer as other plants had to be pulled out from the bundles of flax.

The pulled flax was laid out on bed blocks to rett. It was flipped once and collected from field to dry 28/09/23 (24-37 days retting/ 3.5-5 weeks). We noticed that some seeds were viable and had started sprouting in the field suggesting that in reality we had left the crop too long before harvesting. We also had irregular retting across the crop, probably due to plants being overly deep in places, and also only having time to flip the plants once. It would also be better to avoid retting on weedy beds - at this time in the year they still had a lot of vitality and continued to grow through the laid out flax which was a pain when lifting the crop later. Next year I would flail mow or crimp any bed we laid the flax out on - or if we had tarped beds in the market garden rotations lay the plants out on this.

We also realised after that we should have removed the seeds (“rippling”) prior to retting. An obvious thing in retrospect, as even if not viable as a seed crop this would be another potential harvest either for seeds to eat or use as an oil. It also meant we ended up with a lot of mouse plumping seeds in our field and polytunnel… not ideal for our other cropping plans (or managing the voracious population).

Once retted the bundled to stooks were sent for drying at various places - with Lauriston drying on tables in poly tunnel which was quite humid and probably not the best place for this.

Processing

We tried some very rough on farm processing to understand the quality of the fibres - with some very rudimentary tools (blocks of wood off cuts, nails and combs) we were able to tease out some fibres it would be generous to call ‘homespun’ but it was an enjoyable endeavour and even at this level we could see differences between the varieties in terms of quantity, length and volume etc. It’s also interesting to note the difference in colour between our crop (silvery grey!) and a strick of 100+yr flax kindly gifted to us by Bertas Flax project. I think this is due to the dew retting process and again, something interesting to explore with artists who will be using the fibre product as some natural variations in colour could be encouraged and incorporated into final designs instead of a dye stage. Given the historic abundance of fairytales spinning gold thread and talk of flaxen haired maidens it would be nice to be able to produce a golden crop though and I’m looking forward to hearing from Rosie and team at Fantasty Fibre Mill as they continue their developments with processing experiments and textile productions.

Lessons Learnt

Sowing

Aim to sow in weed free beds with compost amendment with seeds at a higher density - both on the row and between the row (be interesting to see how this impacted height and suppressed branching). Whilst crop fared admirably given its total neglect and weed competition, the flax we grew in 2023 which had been sown in weed free/composted beds was much taller.

Growing

I probably still wouldn’t spend time weeding this crop or irrigating it, but it would definitely be worth sowing it in better conditions in terms of weed pressure and water availability. Could also be interesting to include single beds within the Market Garden vegetable bed blocks which would enable it to receive some irrigation without extra work. Also be interesting to see how it could fit within vegetable rotations given its short growing season e.g. sown after overwintered/spring greens; followed by end of season salads/greens or transplanted winter brassicas. Could also be effectively followed by a late summer or overwinter cover crop.

Harvest

Pull earlier (or at least more timely) and ripple. After retting there were clearly some viable seeds as they started to shoot. Don’t underestimate the number of hands needed (and how much quicker it is without weeds)

Retting

This takes time which needs to be factored in! Probably better to spread thinner and flip more for better standardisation of retting process - also aim to rett for less time. Think we may have over retted which may negatively impact the quality of the fibres. It would be good to collaborate with artisans using the fibres to improve the skill and timings here as it definitely has a huge impact on the quality of fibre. It may be more efficient for the farm to dry the pulled crop and let retting be managed at a later date in collaboration with the textile teams to help better understand our knowledge of this process.

Drying

It would be better to standardise stook sizes and also prepare better locations for drying/storage for example in the rafters of the the packing shed vs. Polytunnel which is still prime real estate at that time of year.

Growing in 2024

We will trial varieties again: whilst Avian seemed to be the winner in terms of yield this year it would be good to trial again - also trial other seed companies varieties not just Elsoms.

We will sow more densely on better prepped beds and potentially incorporate more with vegetable crop rotations within MG bed blocks so we can make use of the irrigation schedule if it’s another drought period. However, given we wouldn’t irrigate if we were scaling up the crops into field production it may be better to be developing more tolerant varieties suited to our region.

We also need to develop our understanding of the actual wholesale/retail value of this as a potential cash crop for fibre artists and/or explore other avenues for income generation e.g. from engaging people in seasonal workshops through from planting to material production. People were very interested in this crop and getting involved in various stages of the crop as well as hands on trying out the processing stages. Ultimately we’d like to be able to better quantify the potential for this as a cash crop in our Market Garden and Agroforestry field production.